Laminated Hardwood vs Laminated Softwood Panels

Unlocking the Potential of Laminated Hardwood and Softwood Panels

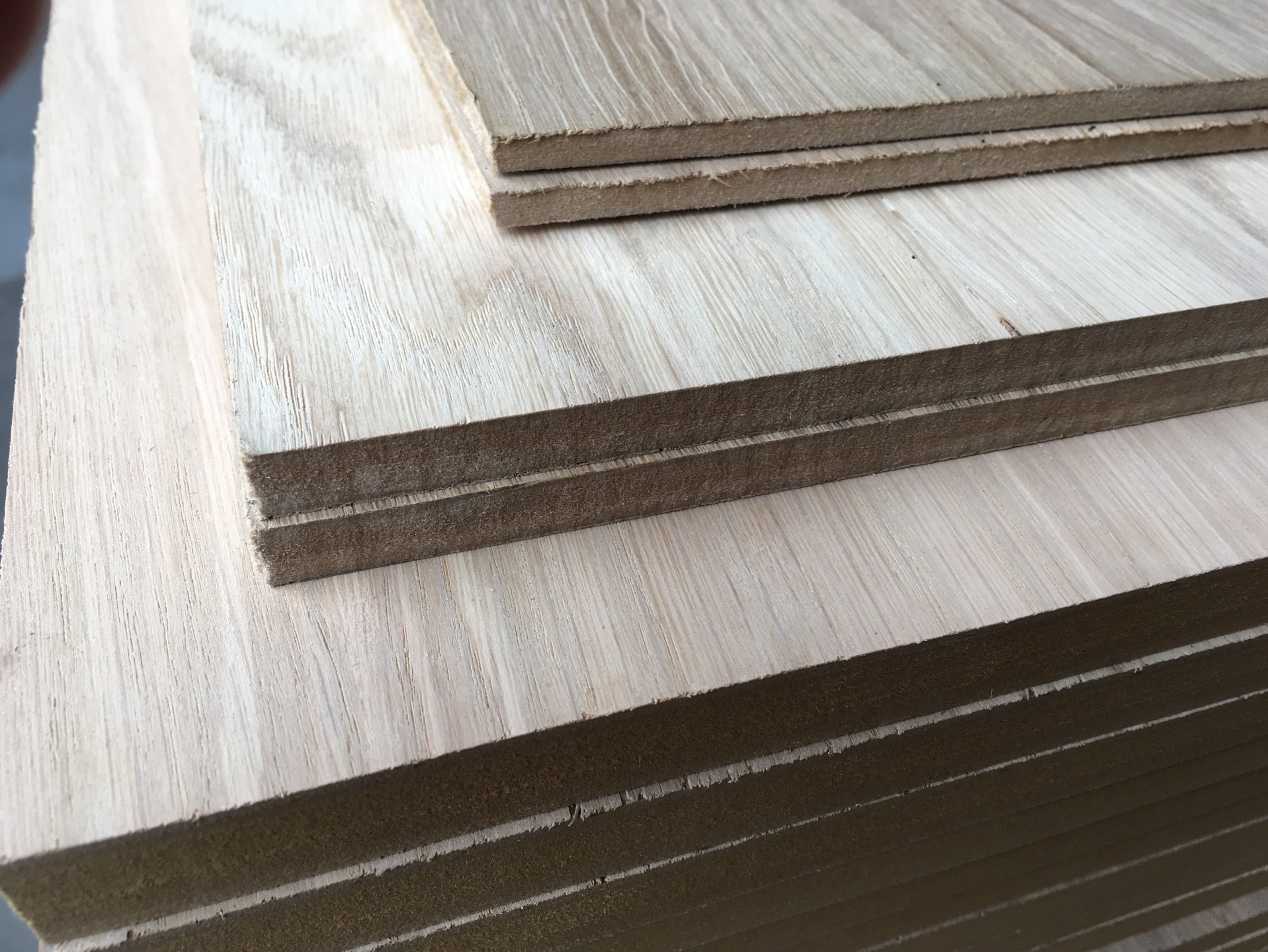

Laminated panels have become a cornerstone in the world of furniture making and interior design. These versatile solid wood sheets offer a perfect blend of durability, aesthetics, and functionality. Whether you're a professional carpenter or a DIY enthusiast, understanding the nuances of laminated hardwood and softwood panels can elevate your projects to new heights.

The Beauty of Laminated Panels

Laminated panels, also known as furniture boards or solid wood sheets, are crafted by joining smaller pieces of timber to create larger, more stable sheets. This process not only enhances the strength of the wood but also showcases its natural beauty.

Hardwood Options

European Oak: A popular choice for furniture grade timber, European oak laminated panels offer exceptional durability and a timeless aesthetic. Its distinctive grain pattern and warm tones make it ideal for high-end furniture and cabinetry.

Poplar: Known for its lightweight and versatile nature, commonly used in furniture/kitchen making.

Softwood Varieties

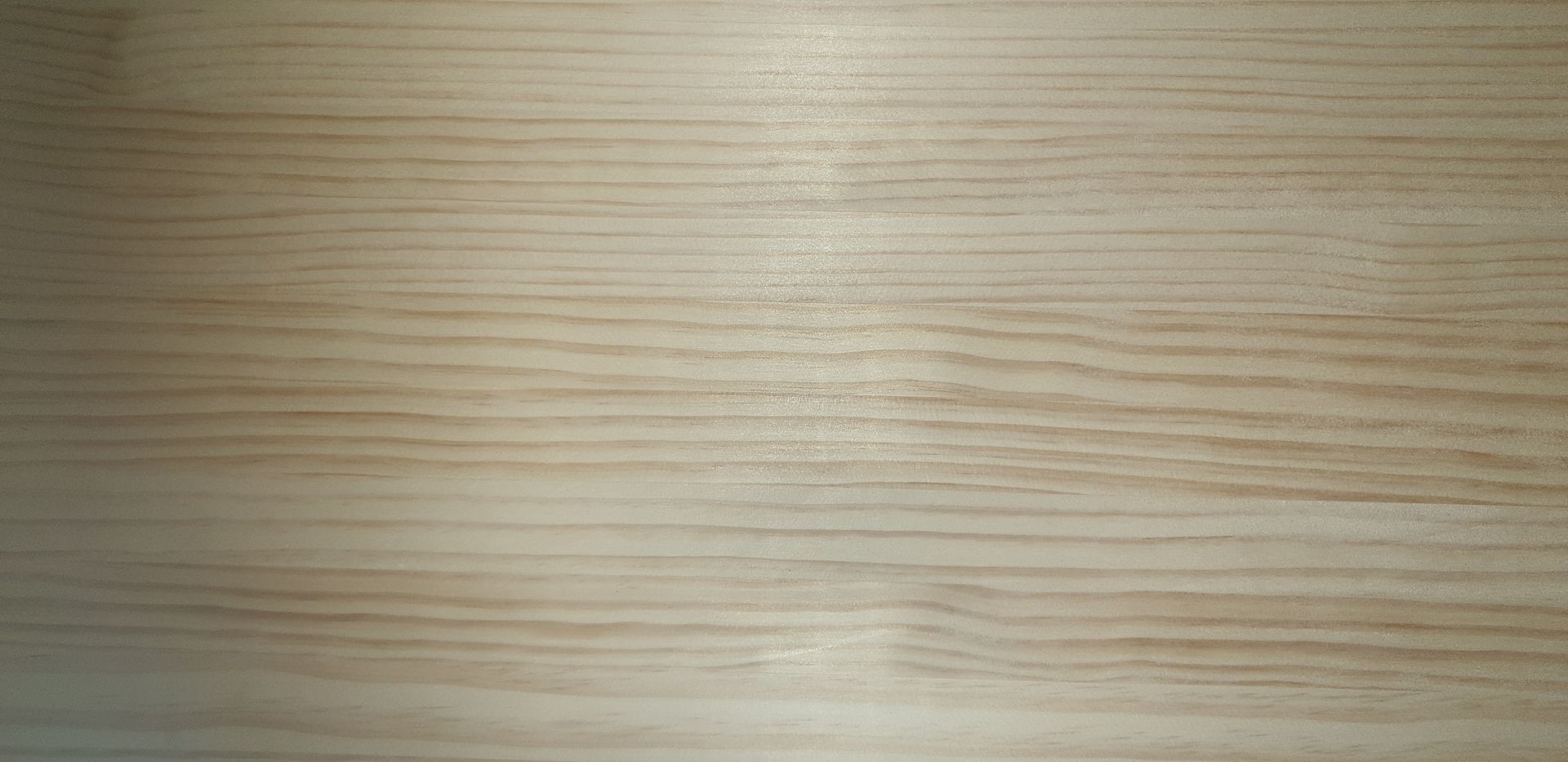

Scandinavian Redwood Pine: This versatile softwood is widely used for furniture timber and interior applications. Its light color and straight grain make it an excellent choice for painted or stained projects.

Radiata Pine: Known for its stability and ease of working, radiata pine boards are perfect for painted furniture and kitchens manufacturing.

Advantages of Laminated Panels

Stability: The lamination process reduces warping and twisting, ensuring your furniture remains structurally sound.

Versatility: Available in various sizes and thicknesses, these panels can be easily cut and shaped to suit your needs.

Cost-effective: Laminated panels offer the look of solid wood at a more affordable price point.

Ready to finish: Many panels come pre-sanded, allowing you to apply your desired finish immediately.

Choosing the Right Panel for Your Project

When selecting laminated panels, consider the following factors:

Intended use: Different woods suit different applications. For example, oak is excellent for durable furniture, while pine is great for painted pieces.

Thickness: Panels typically range from 9mm to 38mm, depending on the required strength.

Grade: Opt for furniture grade timber for visible surfaces and lower grades for internal structures.

Moisture content: All our panels are kiln-dried to prevent future warping or cracking.

Working with Laminated Panels

To get the most out of your laminated panels:

Seal all surfaces: This helps maintain stability and prevents moisture absorption.

Use appropriate tools: Sharp, clean-cutting tools will ensure smooth edges and reduce splintering.

Sustainable Choices

Consider eco-friendly options like paulownia or poplar for projects where sustainability is a priority. These fast-growing species offer lightweight yet durable alternatives to traditional hardwoods

Reliable Timber Supplier

Partnering with a reputable timber supplier like Optimum Timber ensures you receive high-quality, furniture grade timber for your projects. We offer a wide range of options, including European oak, radiata pine, and other popular species. Laminated hardwood and softwood panels offer endless possibilities for furniture making and interior design. By understanding the unique properties of each wood type and choosing the right panel for your project, you can create stunning, durable pieces that stand the test of time. Whether you're crafting a bespoke dining table from solid oak or building custom shelving with pine board, laminated panels provide the perfect foundation for your woodworking endeavors.